Maillefer: By-product separator operating CV Lines responsibly

22 December 2023

By-formation during the Continuous Vulcanizing process has been primarily a cable quality issue, but in this day and age is has equally become an environmental one. Maillefer offers a modern […]

By-formation during the Continuous Vulcanizing process has been primarily a cable quality

issue, but in this day and age is has equally become an environmental one. Maillefer offers a

modern By-product Separation (BPS) system that couples to extrusion lines seamlessly. Here is an

optimal system for extracting by-product in a responsible fashion.

Picture 1. Typical quality issues on the outer cable surface due to by-products

By-product extraction improved

Medium voltage, high voltage and extra high voltage cables are largely XLPE insulated and produced

on CV lines. The crosslinking method employed on horizontal (HVC), vertical (VCV) or catenary

(CCV) CV lines is peroxide based. Unwanted by-products result from this process. If insufficiently

extracted, they will cause cable quality issues. It is best to handle by-product removal carefully and

in a systematic manner.

Improved by-product separation and collection during the CV-process has multiple benefits directly

on the product and also on the neighbouring environment:

Maintaining optimal production conditions

• Stable cooling and heating capacity

• Cleaner cooling water and cooling gas

• Less quality issues with produced cables and scrapped cables

Reduced maintenance work

• Less curing tube & heat exchanger cleaning needed

• Vulcanizing equipment and instruments increased reliability in operation

• Decreased maintenance costs

Environment and Sustainability

• Cleaner exhaust nitrogen gas from CV line to atmosphere

• Less waste water

• Better controlled by-product collection.

The entire BPS loop

Maillefer has continuously developed the by-product removal process as an integral part of CV-line

development. Nowadays, we offer several individual components for by-product removal as a part of

an overall approach. The goal is to secure and maximize customer’s production potential and to

minimize the scrap cable produced.

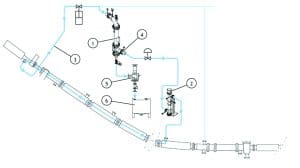

The schema of the BPS loop in a CV process

The BPS with the Gas ReHeater (GRH) component are the most effective and the most essential

parts of a by-product extraction system. The BPS separates the decomposed crosslinking by-products

by condensing associated particles found in the nitrogen flow. The condensate is collected at the

bottom of the unit. The BPS is equipped with a time controlled valve, which purges the liquid waste

collected towards holding tanks.

BPS functionality and construction

The GRH continues by increasing temperature of the gas returning from the BPS. It is located in the

same gas circulation loop as the BPS. The heated gas is injected into the second to last curing tube,

at the same temperature as the nitrogen within the curing tube.

Gas Re-heater (GRH)

Gas Re-heater

Both BPS and GRH are available as upgrades, ready to integrate into any existing CV line, whether a

Maillefer line or other. We provide three main upgrade types for existing CV-lines in order to

improve by-product extraction.

Complete by-product removal system

If the CV-line is not equipped with a by-product removal system, a complete BPS system with GRH is

proposed. A holistic approach is used by studying the by-product removal process for the CV in place,

and a full system is engineered accordingly.

Partial by-product removal system

If the line is already equipped with BPS but without a GRH, it is possible to improve by-product

separation system by integrating the new component into the existing circulation loop and BPS.

Selective by-product removal system replacement

If the existing CV-line is already equipped with a by-product removal system that gives undesired

results, selected elements are replaced accordingly, which may include Maillefer’s BPS and GRH.

High cable value to consider

CV cables are high added value products. Sacrificing cable quality due to insufficient by-product

removal directly effects the bottom line, not to mention product image. Do not hesitate further to

extract your crosslinking by-products effectively and responsibly. We stand ready to offer a solution

that is tailor-made for your specific conditions.

For more information, please contact:

Roger Möller

VP, Maillefer Services

roger.moller@maillefer.net.